CALL TO ACTION

CALL TO ACTION

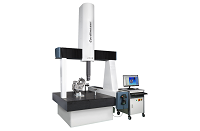

Reliable, high-quality measuring technology, faster and more precise measurements.

Autus Metrology has been involved in co-ordinate measuring machine for many years and we use Accurate CMM.

We have the accurate with a complete range of 3D Co-ordinate Measuring Machine to meet the full requirements of various industries such as Automotive, Aerospace, Ship Building(Marine), Railways & Locomotives, Textiles, and Oil & Gas Industry.

We provide 3D co-ordinate measuring with accurate for all different types of car body parts. we have done more efficiently and successful 3D coordinate measuring. We providing the best 3D coordinate measuring services including accurate CMM. We evolving new reliable, and high-quality measuring technology, we have been continuously shaping our services to meet the growing demand for fast, secure and accurate interactive measuring.

Accurate has a strong team of skilled engineers to provide Measuring solutions for wide range of applications.

| Machine Name | Co-ordinate Measuring Machine |

| Model Name | Cordimesur |

| Machine Size | X-800, Y-1000, Z-600 mm |

| Make | Accurate |

| Resolution( In μm ) | 0.1 μm |

| Accuracy | 2.5+L/350 |

| Temprature | 20°± 1° |

| Linear Speed | 300 mm/s |

| Volumetric Speed | 520 mm/s |

| Machine Table | Granite Material |

| Probe Head | MH8, TP20 |

| Machine Name | Co-ordinate Measuring Machine |

| Model Name | Zeiss Contura g2 |

| Machine Size | X-1000, Y-1600, Z-600 mm |

| Make | CARL ZEISS |

| Resolution( In μm ) | 0.2µm |

| Accuracy | 1.8 micron |

| Temprature | 18 to 20 |

| Probe Head | RDS |

Autus Metrology has also been involved in co-ordinate measuring machines for many years and we use Carl Zeiss CMM.

The affordable CONTURA G2® is ideal for small and mid-sized companies wanting the benefits of high-speed scanning. VAST® scanning technology enables form inspections at maximum speed with high-quality measuring results. Process changes are detected at an early stage, high production quality is ensured and rejected parts are reduced.

We use affordable high-end measuring technology Zeiss Contura g2. In this, The vast scanning technology enables form inspections at maximum speed with high-quality measuring results. Process changes are detected at an early stage, the high production quality is ensured and rejected parts are reduced.